Have you ever wondered what a CNC machine is and how it shapes the world around us? From the tiny phone parts in your pocket to the massive structures in cars and airplanes, CNC machines quietly do a lot of the heavy lifting. At Licht Technology, we believe in making high tech understandable, so whether you’re curious about manufacturing, a hobbyist, or exploring solutions for your business, this guide is for you.

Key Takeaways

- A CNC machine (Computer Numerical Control) automates machining processes, giving precision and repeatability.

- They work via pre-programmed instructions (often from CAD/CAM software), using tools to subtract material from raw stock.

- There are many types: milling machines, lathes, routers, laser cutters, 3-axis, 5-axis, etc.

- Benefits include speed, consistency, versatility, and less waste.

- Knowing how to pick the right type and understanding the limitations matters when choosing CNC for your needs.

What Is a CNC Machine?

So, what is a CNC machine in simple terms? CNC stands for Computer Numerical Control. It’s a system where machines are controlled by computers executing precise digital instructions.

Instead of a machinist adjusting levers manually, the CNC machine is given a coded set of instructions (such as G-code and M-code) that tell it how, when, and where to move, cut, spin, or shape materials.

It’s used in many industries such as manufacturing, prototyping, aerospace, medical devices, furniture, and even the arts. If you need consistency, precision, or the ability to produce complex shapes reliably, a CNC machine is often the way to go.

How CNC Machines Work

Let’s walk through the typical process and see how these machines go from idea to finished part:

- Designing: First, you create a design in CAD (Computer-Aided Design). It might be 2D or 3D, depending on what you want to make.

- Preparing instructions: The CAD model is converted into code via CAM (Computer-Aided Manufacturing) or similar software. This code (e.g. G-code) includes instructions about cutting paths, tools to use, feed rate, spindle speed, and more.

- Setting up the machine: Material (workpiece) is secured, tools are installed, and machine parameters are configured. Sometimes a “dry run” or test run is done to check that everything is correct.

- Machining: The CNC machine carries out the operation: cutting, drilling, milling, or turning, following the programmed paths. The machine may run continuously depending on the task.

- Finishing and Quality Control: Once machining is done, parts may need finishing such as deburring, polishing, or coating. Regulators or machinists check that tolerances, dimensions, and surface finish meet the required specifications.

Types of CNC Machines

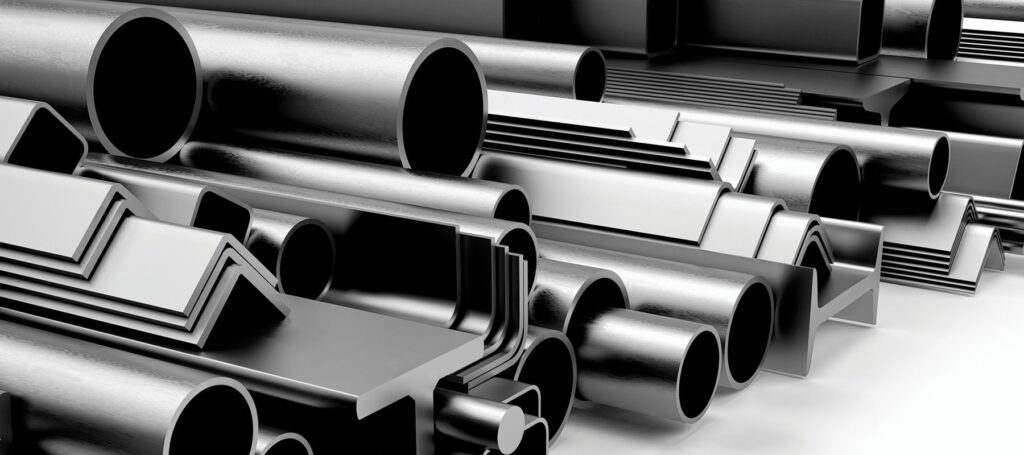

Not all CNC machines are alike. Different types suit different tasks. Here are some common ones:

- CNC Milling Machines: Use rotating cutters to remove material. Great for complex shapes, pockets, and slots.

- CNC Lathes / Turning Centers: The workpiece rotates while the tool moves to shape it. Ideal for cylindrical or round parts.

- Routers: Similar to milling, but often for wood, plastics, or softer materials. Useful for signage, furniture, and decorative shapes.

- Laser Cutters / Plasma Cutters / Water-Jet Machines: Use different energy sources (laser, plasma, or water jet) to cut materials without direct contact. Good for fine, fast cuts and hard materials.

- Multi-Axis CNC Machines (4-axis, 5-axis, etc.): These machines can move the tool or workpiece in multiple axes, allowing for complex shapes, undercuts, fewer setups, and higher precision.

Each type has its trade-offs, such as cost, complexity, material compatibility, setup time, and application.

Key Benefits of CNC Technology

Using CNC machines comes with many advantages, which is why they’re so common in modern manufacturing:

- High precision and repeatability: Once programmed, CNC machines can produce parts that match the design very closely, again and again.

- Faster production times: Automation speeds up machining, reduces manual adjustments, and allows for continuous operation.

- Reduced errors and waste: Less human error and more control mean fewer mistakes and less material scrap.

- Flexibility: Want one prototype or a thousand identical parts? CNC handles both. Need to change designs? Just tweak the digital file.

- Wide range of material options: Metals, plastics, composites, and wood are all common materials that CNC machines can handle.

- Better safety: Since much of the operation is automated, human operators are less exposed to dangerous manual machining tasks.

Of course, there are downsides too. These include high upfront costs, the need for skilled programmers, maintenance, and sometimes limitations in cutting certain geometries. But in many contexts, the benefits outweigh these.

Conclusion

Understanding what a CNC machine is isn’t just for engineers. It’s useful for anyone involved in design, manufacturing decisions, or innovation. These machines are one of the pillars of modern production because they combine precision, repeatability, and flexibility in ways that manual methods simply can’t.

At Licht Technology, we believe in leveraging CNC technology not just for what it can produce, but how it can help businesses gain efficiency, improve quality, and bring ideas into reality. Whatever your goals, whether it’s custom parts, prototypes, or large-volume production, knowing your options goes a long way.

Frequently Asked Questions

Is CNC machining the same as 3D printing?

No. 3D printing is additive (building up material layer by layer), while CNC machining is subtractive (removing material from a solid block). CNC generally gives better material strength and precision for many applications.

What materials can be machined with CNC machines?

Many: metals like aluminum, steel, and titanium, as well as plastics, woods, composites, and even harder materials, depending on the machine and tooling.

What determines how expensive a CNC project will be?

Factors include the complexity of the design (number of axes, undercuts, tight tolerances), material cost, machine setup time, finishing requirements, and the quantity of parts.

Do I need skilled personnel to run CNC machines?

Yes, to some degree. You need people who can design in CAD, convert to CAM, write or adjust code, maintain machines, and verify quality. But automation reduces manual labor in many tasks.

What are common limitations or challenges of CNC technology?

- High initial investment in equipment and software.

- Maintenance and tool wear.

- Difficulty with some geometries or materials.

- Lead times for programming and setup can be relatively long for very custom or complex designs.